You might consider whether small-scale CNC machining would be a good option for your company if it is heavily dependent on CNC machining.

Standard CNC machining is not without its problems, but small-batch CNC machining is full of benefits.

What is small batch CNC machining?

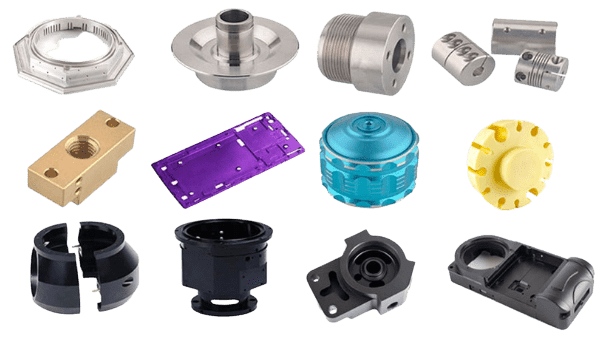

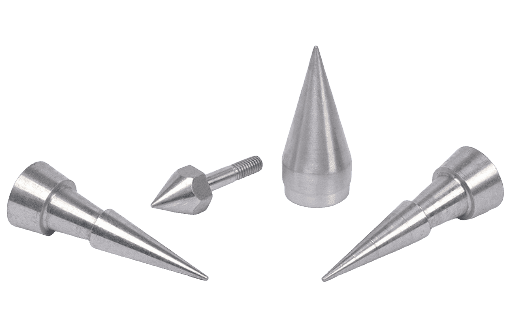

CNC machining in small batches is the most common method of giving metal and plastic components a machined finish during discrete manufacturing steps. CNC machining is used to produce complex 3D product forms in small batches.

The most important step in manufacturing is the cutting process, which converts a tool into three dimensions.

CNC machining in small batches is also used to remove waste and produce the final product according to specification.

The movable cutter is responsible for cutting chips from blocks of materials. These components can be found underneath the blade's rotating table. Computer programs control movement in small batches of CNC machining.

Because of its high precision and low waste, small batch CNC machining is becoming more popular in the manufacturing sector.

Benefits of small batch CNC Machining

Production in low volumes

The greatest benefit of small-run CNC machining is its low volume. This allows for the designer to show off their originality in the final product.

The key principle of product development when creating new products is to use low-batch CNC machining to produce small quantities.

Verification of the Design

CNC machining in small batches offers many benefits. One of them is design verification. This helps to determine if the structure is logical.

This allows designers and manufacturers to better understand the issues and find solutions.

Increased production speed

The automated machining process is the best source for increasing the speed and quality of small batch production.

This means that you won't have to take unplanned breaks during work, which can reduce the speed of your processing.

Cost-Effective

CNC machining in small batches is far more cost-effective than any other type of machining because it doesn't require an operator for every machine.

It can function at its best with a smaller number of operators, making items in small batches and minimizing errors.

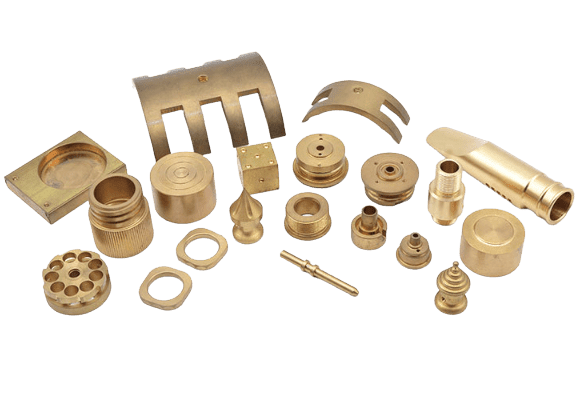

Here are some design guidelines to consider for small CNC machining

Here are some design considerations to consider before you start small-batch CNC machining.

Cavity Depth

CNC machines' cutting tools should not be permitted to touch the interior of goods beyond what is required. This can be achieved by restricting the internal cavity depth to a maximum of four times the tool's width.

Materials and Surface Finish

Cost of the final product shouldn't be affected by the materials you choose for CNC machining. They must reduce the time required to produce. A finish can also increase the value of the surface.

Feature Alignment

The CNC machining characteristics and the difficulty of the components should be coordinated. Manufacturing a component that is difficult will lead to an increase in manufacturing costs. It is important to make sure that compensation is made between the manufacturer and the repositioning.

Internal Edges

The pieces' internal edges cannot be wider than one third of their cavity depth. It is important to ensure that the pieces' internal vertical edges are not wider than the cavity depth.

Avoid excessive tolerance of the design

There is no need to increase tolerance if your product has sufficient tolerance. The increased tolerance will result in a higher repeatability, which will increase the annual cost.

Drawings

A manufacturing drawing must be included in the CAD model. This design guideline allows you to customize the threads and tolerances which significantly reduces the time required for setup.

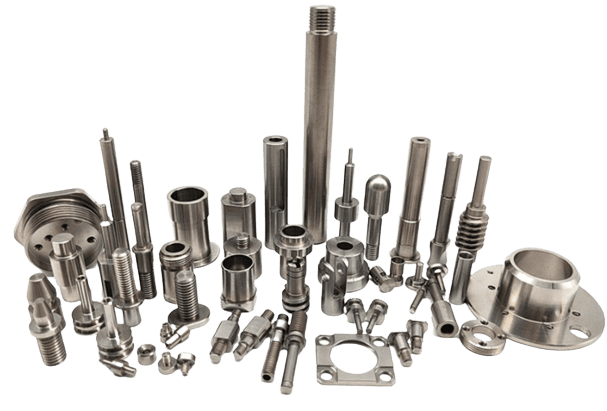

Machine Application of Small Batch CNC Machining

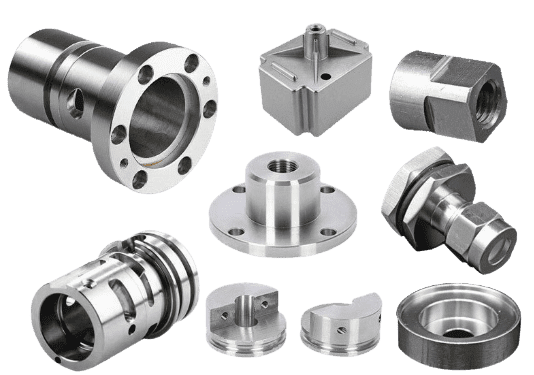

Here is a list containing the machines that can be used in CNC machining small batches.

CNC Drilling

Multi-point drill bits are an integral part of the machining process we are discussing. This drill bit leaves holes in workpieces that are cylindrical in form.

This procedure can also be used to process holes that are vertically aligned in diameters that correspond to the surface of the workpiece.

CNC Milling

A variety of points on a cutting tool can be used to remove material from the workpiece during this process.

This operation includes face milling, reducing shadow and cutting deep voids.

CNC Turning

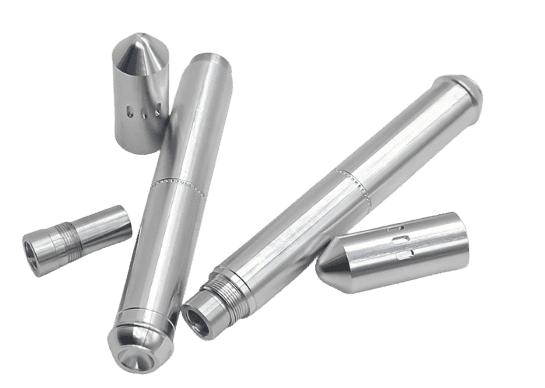

This method of CNC machining can be used in conjunction with single-point cutting tools, which are used to remove spinning materials from components. This technology can be used for small-scale manufacturing.

It also ensures that circular pieces are produced with greater precision in their dimensions.

EDM Machining

This method of machining can be connected to the stage known as the molding stage in metal manufacturing, where the components are formed into their appropriate forms.

Any superfluous material can be removed from the workpiece by the fast current discharges between the electrodes.

Grinding without center

This machining process works in conjunction with the abrasive-cutting process to remove the material from the workpiece.

It doesn't meet the requirements to use a fixture or spindle that holds and positions the workpiece in its place.

Surface grinding

This technique gives flat surfaces of items a smooth finish. That is why it is used.

Abrasive machining is a method that uses a large number of spinning wheels coated with coarse particles.

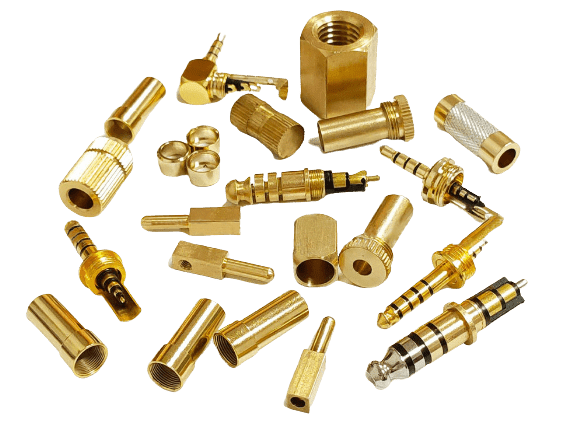

Small Batch CNC Machining Finishes

Here's a list of different finishes that can be created using small-scale CNC machining.

Bead blasting

This particular finish is produced using CNC machining in small batches. It has a matte appearance with a fine texture. Its primary purpose is to enhance the visual experience.

Anodizing Type III (Hardcoat)

When the CNC process is small-batch, the ceramic coating is applied to the surface of the component. It is highly resistant to corrosion and wear. It provides a substantial amount of protection, compared to type II.

As Machined

The finish is very smooth and has few visible tool marks. You can adjust the required surface polish to any distance between 1.6 and 0.4%.

Powder Coating

This finish can be combined with powder coating the item's surface. This is one of the CNC finishes that can be produced in smaller batches and has a greater resistance to anodizing.

Why is it important to use CNC Machining for Batch Production?

CNC machining is essential when producing batch quantities. This technique plays an important role in the product's accuracy, high tolerability, and overall quality.

CNC machining is a popular choice for large enterprises. This procedure can only be justified by the use of high-quality machines.

A CNC machine specialist can also direct batch production, which is much faster and more frequent than hand machining.

CNC machining is essential in batch production. The equipment is well-programmed to ensure consistent quality jobs.

CNC machining is a great option for small batch manufacturing. However, it can also be very cost-effective. CNC machining is gaining popularity because of this.

Contrary to other machines of its type, this machine does not require expensive setup. It just requires a small amount of programming and maintenance.

Conclusion

By including production engineering drawings into the CAD model, setup times can be cut. This can include details like threads, tolerances and surface polish.

Remember that the final product's needs will dictate the design. These recommendations are not intended to show you how to reduce costs or cut down on time. A CNC machining company is the best way to create low-volume parts at the lowest cost.