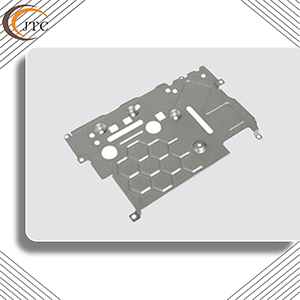

CNC bending or computer numerical control bending is just one of the many manufacturing techniques used by JTC-Machining. Technology enables engineers to use large industrial machines to CNC bend metal sheets of any length from a few millimeters to several meters, then punch, surface, quality check, and deliver to customers qualified, on-time, small to high volume products.

What is CNC sheet metal bending?

There are two methods for CNC bending. The first uses a CNC press brake, which can be attached to the bottom bed. Engineers use the V-block tool to hold the metal in place, while the upper beam takes the force of the V-blade tool. This is called downshaping. The second way of CNC bending is the opposite, when the upper forming machine moves the bottom bend and holds the upper beam in place. Both methods end up yielding the same result, so engineers have limitless options for their designs.

CNC press brakes can be programmed to handle a wide variety of sheet metal parts. The programmable backstop (the metal part that needs to be bent) determines the flat back distance. JTC engineers also programmed the V-blade, where the V-shaped block is critical to the metal bend angle; the more times the V-shaped blade penetrates the V-shaped block, the more severe the V-bend in the final product. CNC program positioning combines various bend lengths and angles with sheet metal to determine the location and angle of each specific sheet metal part.

CNC bending machines determine the length of sheet metal parts that can be bent. The thickness of the material will be consistent with the tensile strength and tonnage of the material the machine can handle. The larger the lower V-block opening, the larger the sheet metal gauge engineers can use to bend the metal. When the V-block is more open, the inner radius of the bend is wider.

Sheet Metal Forming By Raw Materials

JTC-machining has the knowledge and experience to bend and form stainless steel, carbon steel, and aluminum sheet metal to your custom specifications. We understand that sheet metal bends can vary depending on the type of material, its weight, thickness, and gauge.

JTC processes highly cosmetic sheet materials through the automated forming process, including:

|

|

CNC METAL BENDING & FORMING APPLICATIONS

Using the Salvagnini P4 automated panel bending machine, JTC-machining has the capability to bend and form sheet metal into a variety of tools based on your application. The blank is moved on a horizontal plane by the manipulator. A rotator fitted on the manipulator quickly and accurately places the side to be bent in front of the press. The blank holder holds the blank firmly in position. The bending unit and its blades can then make any number of bends, up or down, in rapid succession.

Sample Applications of CNC Panel Bending & CNC Sheet Metal Forming:

|

|

Sheet Metal Bending Case Study

|

|

|

|